The Opti-Kap 3000 series is a heavy duty through-feed optimizing cross-cut saw, characterized by a high production capacity of all workpiece dimensions.

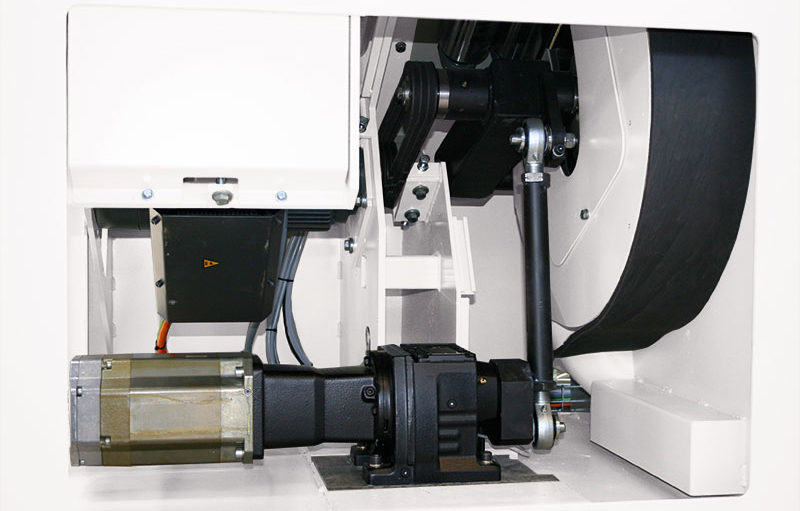

The optimizing cross-cut saw is manufactured in a particularly durable fashion with mechanical components of extremely high quality. In order to achieve the accuracy and capacity required in large workpiece dimensions, the saw is equipped with 6 servo driven bottom rollers and 6 pneumatically activated pressure rollers. Both the driven and the pressure rollers are double supported, to ensure maximum contact to the processed workpieces.

The Opti-Kap 3000 series automatically recognizes the lengths as well as marked or scanned defects, and cuts the workpieces into components with an accuracy of ± 1 mm (0.039”) in cross-cut lengths up to 1,000 mm (39’’).

The Opti-Kap 3000 can be combined with a wide range of material handling such as Opti-Feed and Opti-Stack solutions, and can further more be equipped with many optional features to be able to meet any customers’ production requirements.

It is also possible to add an automatic scanning system to the the Opti-Kap 3000 that identifies the characteristics of the wood, to achieve the best possible utilization of your staff and wood resources.